Small Lab Vacuum Homogenizer Emulsifying Mixer

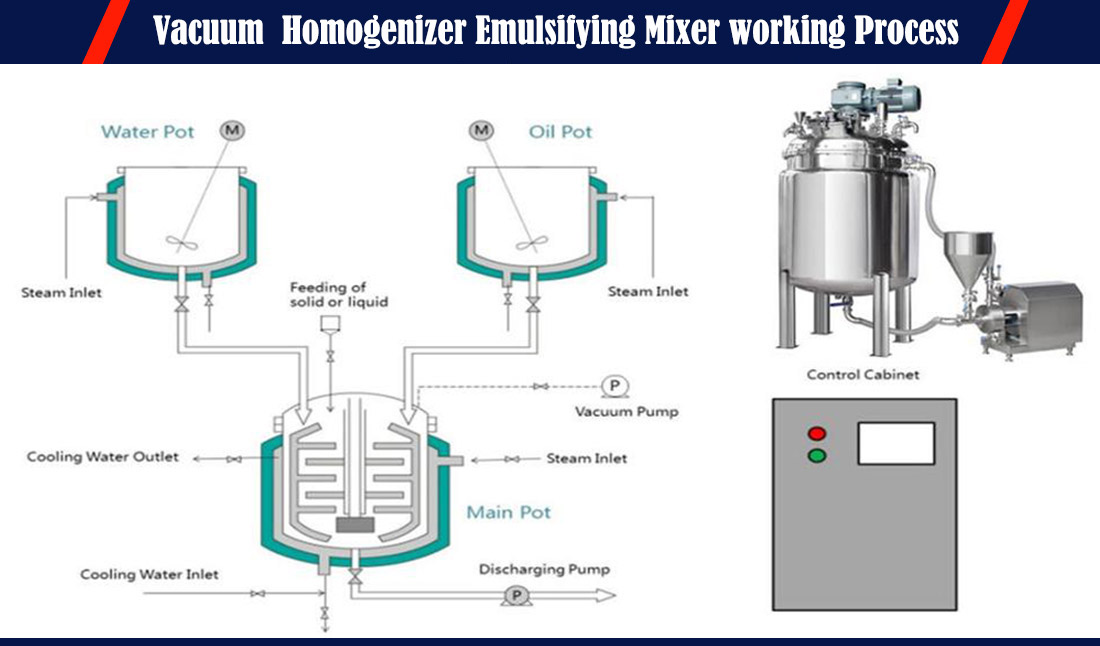

Small Lab Vacuum Homogenizer Emulsifying Mixer is a compact laboratory device for emulsification and homogenization processes. It combines vacuum technology, high shear forces, and emulsification techniques to provide researchers with an efficient and precise experimental method.

Always on time

Always on time Acceptable price

Acceptable price Excellent quality

Excellent quality

Description

Feature&Application

Factory Strength

Small Lab Vacuum Homogenizer Emulsifying Mixer is a compact laboratory device for emulsification and homogenization processes. It combines vacuum technology, high shear forces, and emulsification techniques to provide researchers with an efficient and precise experimental method.

This small-scale equipment is suitable for various laboratory applications, such as liquid-liquid mixing processes in industries like food, pharmaceuticals, chemicals, coatings, cosmetics, and more. It offers the following advantages:

High Efficiency: The powerful shear forces generated by high-speed rotating agitators or blades can quickly and effectively break down and mix droplets.

High Precision: The application of vacuum technology helps reduce bubbles and volatile components, ensuring product purity and quality.

Ease of Operation and Maintenance: The equipment is designed with user-friendliness in mind, making it easy to operate. Additionally, component replacement is simple, facilitating cleaning and routine maintenance.

Versatility: It is suitable for various laboratory applications, including liquid-liquid mixing processes in industries like food, pharmaceuticals, chemicals, coatings, cosmetics, and more.

In conclusion, the Small Lab Vacuum Homogenizer Emulsifying Mixer is a compact device designed for emulsification and homogenization in a small laboratory environment. It offers efficient, precise, and user-friendly results, making it an invaluable tool for researchers.

Gangben mixer factory produces a variety of vacuum homogenizing emulsifier types, which homogenizing system is divided into upper homogenization, lower homogenization, internal and external circulation homogenization, mixing system adopts positive and negative two-way wall hanging mixing paddle, lifting system is divided into electric lifting and hydraulic lifting, can be customized according to customer requirements of various specifications of high quality emulsifying machine products. Triple mixing adopts imported inverter speed regulation, which can meet the production needs of different processes.

The use of imported and end mechanical sealing effect, Germany homogeneous structure technology, the highest emulsification speed up to 3400 RPM, the highest shear fineness up to 0.2~5μm;

Vacuum defoaming makes the material meet the aseptic requirements, and adopts vacuum suction, especially for powder materials, and uses vacuum inhalation to avoid dust flying.

The main pot pot cover can be selected lifting device, the cleaning effect is more significant, the pot body can be tilted discharge.

The pot body is welded with three layers of imported stainless steel plates, and the tank body and pipeline are polished or matte, fully in line with GMP requirements.

The tank can heat and cool the material, and the heating methods are mainly steam heating and electric heating.

In order to ensure more stable control of the whole machine, the electrical appliances are imported and can fully meet international technical standards.

Application Area

Lab Vacuum emulsifying mixer machines are used in many application area,as follows:

Daily chemical products: used in the production of emulsions, creams, shampoos, shower gels, etc.

Biomedicine: used in the production of emulsions, ointments, oral liquids, etc. for medical purposes.

Food industry: used in the production of emulsified food, such as yogurt, ice cream, cheese, etc.

Paint and ink: used in the production of emulsified paints and inks.

Nanomaterials: used in the preparation of nanomaterials.

Petrochemical industry: used in the production of emulsified petroleum products.

Printing and dyeing auxiliaries: used in the production of emulsified paper treatment agents.

Pesticides and fertilizers: used in the production of emulsified pesticides and fertilizers.

Plastic and rubber: used in the production of emulsified plastic and rubber materials.

Electric power and electronics industry: used in the production of emulsified insulation materials and electronic components.

Other fine chemical engineering fields: such as ceramics, glass, metal processing, etc.

In short, vacuum emulsifying machines have a wide range of applications and are mainly used to produce emulsified products to improve product stability and performance in various industries.

Gangben mixer manufacturer specializes in the research, development, production, and sales of mixing machines and filling machines. Main products include vacuum emulsifying mixer machines, high shear emulsifying mixer machines, vacuum homogenizing emulsifying mixer, filling and sealing machines, and liquid filling production lines. We have a modern production workshop and environment, using advanced equipment manufacturing technology and strict process quality management and control to ensure that all products are zero defects before leaving the factory.

Gangben mixer factory has obtained multiple patents for the research and development of emulsifying machines and planetary mixing machines, ISO quality management system certification, and international CE certification. Our product quality is up to standard, with quality guarantee, and we manufacture good quality mixing machinery to improve your production efficiency and save costs for your company.

-

PrevLaboratory Homogenizer Emulsifying Mixer

-

NextNone

Recommend Products

-

5L Lab Vacuum Emulsifying Mixer

5L Lab Vacuum Emulsifying Mixer5L Lab Vacuum Emulsifying Mixer is a compact and efficient device designed for small-scale laboratory experiments and research projects. It combines vacuum technology with emulsification and homogenization capabilities to achieve high-quality emulsions in a controlled environment.

-

Lab Vacuum Homogenizer Emulsifying Mixer

Lab Vacuum Homogenizer Emulsifying MixerLab Vacuum Homogenizer Emulsifying Mixer is a highly specialized device designed for laboratory research and development. It combines vacuum technology, high shear force emulsification, and homogenization techniques with advanced control systems, providing a highly efficient, precise, and repeatable experimental method for researchers.

-

Laboratory Homogenizer Emulsifying Mixer

Laboratory Homogenizer Emulsifying MixerLaboratory Homogenizer Emulsifying Mixer is a device designed for emulsification and homogenization processes in a laboratory setting. It combines emulsification techniques, high shear forces, and vacuum technology to provide researchers with an efficient and precise experimental method.

Recommend Faq

-

Apr 17,2025

Apr 17,2025The Future is Here: Vacuum Emulsifier Homogenizer Mixer Drives Innovation in Emulsification and Homogenization Technology

-

Apr 17,2025

Apr 17,2025Revolutionizing the Future: The New Vacuum Emulsifier Homogenizer Mixer Leads Manufacturing Technology Trends

-

Apr 11,2025

Apr 11,2025Innovative Vacuum Emulsifier Homogenizer Mixer for Seamless Emulsification by Jiangsu GangBen Mixer Manufacturer

English

English Russian

Russian French

French Spanish

Spanish Portuguese

Portuguese Korean

Korean Japanese

Japanese Thai

Thai